Partner description:

Valeo is an automotive supplier and partner to all car manufacturers worldwide. As a technology company, Valeo offers innovative products and systems that contribute to reducing CO2 emissions and increasing road safety. Valeo has established itself as a global leader in driver assistance sensors that enable highly accurate perception of the vehicle's surroundings. Valeo has 190 plants, 20 research centers, 43 development centers, and 15 sales platforms, and employs 112,700 people in 29 countries worldwide.

Role in the project:

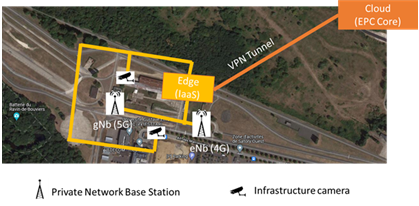

Valeo plays a central and comprehensive role in the EEA4CCAM project. As Work Package leader (WP1), we are significantly involved in the specification, conception, development, and demonstration of both hardware and software building blocks for the future E/E architecture. In addition, Valeo is also responsible for preparing the deployment of hardware and software components within the edge-cloud continuum (Task T3.3), a critical step for integration and demonstration. Furthermore, Valeo is a key player in the Level 4 automation use cases, particularly in developing and showcasing autonomous parking solutions, which includes providing essential sensor setups and testing facilities. The technological expertise in sensor and processing technologies is crucial, contributing to the advancement of these areas for CCAM applications with a focus on seamless integration into future E/E architectures. Valeo's involvement spans across various Work Packages (WP1, WP2, WP3, WP4), actively contributing to all project phases, from requirements definition to demonstration and exploitation. Beyond technical contributions, we are also responsible for creating advertising material to disseminate project knowledge and results. The substantial commitment is underscored by the significant resource contribution of 61.3 person-months to the project